Plastic Gears – Lightweight and Rust-proof

Materials used in plastic gears are, in general, engineering plastics such as polyacetal (POM) and MC Nylon which is essentially polyamid resin. In addition, U-PE and PEEK can be used.

When there is a large temperature fluctuation in the application environment, when the diameter is large or when there is load on its keyway, metal hub made of S45C or stainless steel may sometimes be used. In these cases, the teeth portion and the hub portion are attached together with screws. If it is not possible to screw together, two parts are fused together and made into fused gears. KHK’s fused gears are designed in such a way that the holding strength of the fused surface is stronger than the tooth strength.

The positive characteristics of plastic gears include being lightweight, non-rusting, quiet, injection molding enabling low cost and large production, and able to operate without lubrication by mating with metal gears. On the other hand, low strength, tendency to hold heat, large dimensional change including backlash compared to metal, etc. are some of the points requiring caution. The degree of dimensional changes that occur with plastic gears depend on the ability to resist temperature change, moisture absorption rate and resistance to chemicals.

As far as the applications of plastic gears, they are used in varying industries such as food production machines, consumer electronics, chemical, toy, and medical equipment industries.

At KHK, the bending strength of plastic gears are computed with the Lewis formula. On the other hand, the tooth surface strength calculation is based on the manufacturer of MC Nylon and needs no consideration.

DSF

Acetal F-Loc Gears

Module : 0.5 – 1

Material : Polyacetal/SUS303

Hardening : None

Tooth finish : Cut (non-ground)

Grade : JIS N10 NOTE 1 (Please see details on PDF)

Gears made of polyacetal. Locking Hub allows easy attachment.

Click Here to Select Spur GearsNSU

Plastic Spur Gears with Steel Core

Module : 1 – 3

Material : MC602ST/S45C

Hardening : None

Tooth finish : Cut (non-ground)

Grade : JIS N9 (Please see details on PDF)

Steel hubs are fused and fixed to reinforced nylon gears for secure fastening.

Click Here to Select Spur GearsPU

Plastic Spur Gears with Steel Core

Module : 1 – 2

Material : MC901/SUS303

Hardening : None

Tooth finish : Cut (non-ground)

Grade : JIS N9 (Please see details on PDF)

Stainless steel hubs are fused and fixed to nylon gears for secure fastening.

Click Here to Select Spur GearsPS / PSA

Plastic Spur Gears

Module : 1 – 3

Material : MC901

Hardening : None

Tooth finish : Cut (non-ground)

Grade : JIS N9 equivalent

Nylon gears can be used with no lubrication.

Click Here to Select Spur GearsDS

Injection Molded Spur Gears

Module : 0.5 – 1

Material : Duracon (R) (M90-44) NOTE 2

Hardening : None

Tooth finish : Injection molded

Grade : Equiv.to JIS N12 (Please see details on PDF)

Low-priced gears made through injection molding. Suitable for light loads.

Click Here to Select Spur GearsDRF / DRFD / DRFK

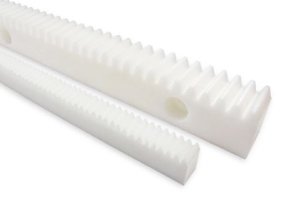

Plastic Racks

Module : 1 – 3

Length : 500,1000mm

Material : Polyacetal

Hardening : None

Tooth finish : Cut (non-ground)

Grade : KHK R001 5 (Please see details on PDF)

Racks made of polyacetal with shorter overall length than nylon, making them suitable for joining together.

Recommended mating pinion

SUS, SUSA

PR /PRF

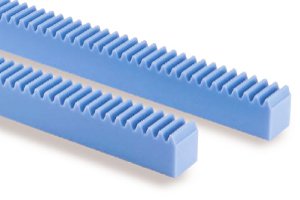

Plastic Racks

Module : 1 – 3

Length : 500,1000mm

Material : MC901

Hardening : None

Tooth finish : Cut (non-ground)

Grade : KHK R001 5 equivalent

Nylon racks can be used with no lubrication.

Recommended mating pinion

SUS, SUSA

DR

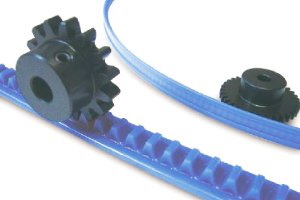

Molded Flexible Racks

Module : 0.8 – 2

Length : 2000mm

Material : Duracon (R) (M25-44) NOTE 2

Hardening : None

Tooth finish : Injection molded

Grade : KHK R001 8

Thin plastic racks that can be bent.

Recommended mating pinion

SSDR

PM

Plastic Miter Gears

Module : 1 – 4

Material : MC901

Hardening : None

Tooth finish : Cut (non Ground)

Grade : JIS 4 equivalent

Nylon gears can be used with no lubrication.

Click Here to Select Miter GearsDM

Injection Molded Miter Gears

Module : 0.5 – 1.5

Material : DURACON (R) (M90-44) NOTE 2

Hardening : None

Tooth finish : Injection Molded

Grade : JIS 6

Low-priced gears made through injection molding. Suitable for light loads.

Click Here to Select Miter GearsPB

Plastic Bevel Gears

Module : 1 – 2

Speed ratio : 1.5 – 3

Material : MC901

Hardening : None

Tooth finish : Cut (non-ground)

Grade : JIS 4 equivalent

Nylon gears can be used with no lubrication.

Click Here to Select Bevel GearsDB

Injection Molded Bevel Gears

Module : 0.5 – 1

Speed ratio : 2

Material : Duracon (R) (M90-44) NOTE 2

Hardening : None

Tooth finish : Injection molded

Grade : JIS 6

Low-priced gears made through injection molding. Suitable for light loads.

Click Here to Select Bevel GearsPN

Plastic Screw Gears

Module : 1 – 3

Material : MC901

Hardening : None

Tooth finish : Cut (non-ground)

Grade : JIS N10 equivalent

Nylon gears can be used with no lubrication.

Click Here to Select Screw GearsPG

Plastic Worm Wheels

Module : 0.5 – 3

Speed ratio : 10 – 60

Material : MC901

Hardening : None

Tooth finish : Cut (non-ground)

Grade NOTE 3 : KHK W002 5 equivalent

Worm wheels made of MC nylon. Can be used with no lubrication.

Used in combination with SW and SUW.

Mating worm : SW, SUW

Click Here to Select Worm Gears

[NOTE 1] The product accuracy class having a module under 1 corresponds to 'equivalent' as shown in the table.

[NOTE 2] "Duracon (R)" is a registered trademark of Polyplastics Co., Ltd. in Japan as well as other countries.

[NOTE 3] The precision grade of KHK stock worm gears controls the product quality based on the KHK standards. Please see "Precision of Worm Gears" on Page 396 in the Selection Hints section for details.

Introduction

The plastic gear is new compare to the steel gear, and it originates from the introduction of engineer plastic that is abbreviated to En-pla. In recent years, even a material called super engineer plastic has been introduced while making a contribution to the performance improvement of the plastic gear.

Plastic gears manufactured by KHK

Plastic spur gears :

We offer you various types of plastic spur gears according to usage and necessary strength.

DSL series allow you to fasten gears and axes easily.

NSU and PU series use nylon teeth and metal core to facilitate hole machining and key groove machining which are necessary to fasten gear and axis, and to strengthen fastening parts of gears and axes where excessive loads are applied to.

In addition, MC nylon which is improved in strength and thermal characteristics is used for standard type PS, and we also offer PSA as a version without boss.

We also provide DS as the low-strength plastic gears realizing the cost reduction through injection molding.

Plastic Gear made by 3D Printer

Plastic gear rack :

We have several types of plastic rack.

MC nylon (reinforced plastic) is used for standard type PR. Using PR as the base, end surface work is performed for PRF type which enables connection with several racks.

For DRF series, polyacetal (equivalent to POM and Duracon) has realized the water absorption resistance better than MC nylon, reducing the change of rack length caused by water absorption.

DRF-based DRFD and DRFK series have mounting holes on the rack to be more user-friendly.

Being manufactured by injection molding, DR has a unique and flexible character, and comes in handy when using rack and pinion in a curved place.

Plastic bevel gears :

KHK offers MC nylon-made PM (plastic miter gear), so-called engineering plastic, PB (plastic bevel gear), polyacetal-made DM (miter gear made by injection molding), and DB (bevel gear made by injection molding).

Plastic worm gears :

KHK covers two types of plastic worm gear, PG (MC901-made worm gear) and DG (polyacetal-made worm gear) to respond to various customer’s requests.

Tips in using the plastic gear

The most plastic gears that are in use nowadays are made from either Duracon with milky white color (polyacetal resin) or MC nylon with blue color (polyamide resin).

The Duracon may be cheaper, but it is recommended that you decide between these materials after taking the strength and water absorption rate into consideration.

Attentions in using the plastic gear

Generally, no lubricant is necessary for the plastic gear. Because no oil bath or grease filling is necessary, it can be used under the clean environment. Though it is possible to use under relatively high temperatures, you may avoid it for the consideration to the allowable temperature of the bearing.

Recommended usage location of the plastic gear

Although the plastic gear has wear resistance and silence on the rotation, its strength is less than the steel gear, thus it is suitable for the drive system of office automation equipments, the loader of electric goods, and toys.

Plastic gear materials

The materials used for producing plastic gears are typically one of two types.

One type of engineering plastic is called POM. It is also known by the tradename Duracon or its generic name, acetal copolymer. The other is MC nylon. It’s a polyamide resin and is called nylon 6 as well.

Because both are smooth materials, they don’t typically require lubrication with grease or oil. They are softer than metals, thus effective for noise reduction with a high vibration absorptance. The common characteristics of both materials are that they are lighter than metals and resistant to corrosion from salt.

When comparing a POM gear and MC nylon gear, the biggest difference one may point out is the difference in the forming method. POM is made by pouring melted resin into a metal mold while applying pressure, which is called injection molding. Due to its high formability, the gear shape can be obtained by simply having a mold in the gear shape. On the other hand, MC nylon gears are generated by cutting. Similar to casting metal gears, melted resin is poured into a mold without applying pressure to create a rough shape such as cylinder, pillar, or disk and then the gear teeth are formed by cutting.

With those differences, POM is suitable for producing small gears in larger quantities and MC nylon is suitable for producing large gears or small lot gears.

Another big difference between POM and MC nylon can be found in absorbency. Though it depends on the environment, MC nylon absorbs water 10 times more than POM does. Absorbing water lowers dimensional accuracy and consequently produces noise or lowers the transmission efficiency of torque. Additionally, a deterioration of resin occurs due to hydrolysis, therefore POM is more suitable as a material of gears that are going to be used in high humidity or where water touches.

Furthermore, there’s a difference in mechanical properties as well. MC nylon is better in terms of mechanical properties because of the tensile strength and bending strength. For instance, the bending strength of MC nylon is 1.2 times stronger than POM. As a plastic gear, MC nylon is more suitable when a large force is applied.

One should choose a suitable material after considering the number of gears that are needed, the force on the gear, and also surrounding environment such as humidity and chemicals.

Lubrication of plastic gears

Plastic gears are often made from nylon resin or POM.

These materials are smooth and have high slidability and in many cases they don’t require lubrication with oil unlike metal gears. However, plastic is softer compared to metal and has a characteristic that it is prone to incurring damage on the tooth surface due to friction, hence, consideration should be given for the use of lubrication depending on the kind of plastic to use, force on the gear, and number of rotations. When doing so, one must pay attention to the deterioration of plastic with oil. Because plastic has a characteristic of deteriorating with oil, lubricants that are used for metal gears cannot be used.

The molecular structures of oil and plastic are relatively similar and both have a long stretched structure like a chain. Matters with a similar molecular structure are easy to mix, and mixing means the molecules of one matter get in between the molecules of the other matter. That is, the molecules of oil are easy to get into those of plastic. This phenomenon is called swelling. When it happens, the long chain of plastic molecules undergoes hydrolysis by taking in water from the air, making them come apart. The phenomenon of the plastic molecules coming apart like so is called deterioration.

For plastic to swell from oil, it is said in general, that a constant stress must be applied to plastic. When stress is applied to plastic, molecules are deformed slightly and oil molecules get into those spaces. However, because gears are the component to transmit power, pressure is applied to plastic gears. Thus, plastic gears are under an environment where deterioration from oil is likely to happen. Then how should the lubrication of plastic gears be done ?

As for the oil used for lubrication of plastic gears, generally one without polarity is used. Polarity means having different properties in a molecule, and a typical substance is a surfactant, which is in washing materials. Since in these molecules, one is hydrophilic group and the other is lipophilic group, the lipophilic group tends to get in between the plastic molecules.

As for the oil that is hard to deteriorate plastic and does not have polarity, there are synthetic hydrocarbon oils. A grease mixed with an expanding agent and addition agent is used in order to make the synthetic hydrocarbon oil a base and give the proper characteristics for the viscosity and temperature.

Injection molding of plastic gears

Forming method of gear is the biggest difference between plastic gears and metal gears.

For metal gears, milling machines or hob machines are mainly used to cut gears out of disk-like (or cylindrical) metal. In contrast, most plastic gears are molded into gear shapes early in a process. Why is there such a difference between them ?

One reason is the molding method of plastic parts. Thermoplastic resin, another name of plastic, means the resin which can change form by heating. Plastic parts are made by pouring heated and melted resin into metal dies while applying pressure. This method is called “injection molding”.

Metal can be also melted and poured (or casted) into dies. However, the melting point of metals is much higher than plastic and largely contracts as it cools down. Therefore, it is very difficult to manufacture parts of high dimension accuracy such as tooth flanks of gears. In the general method of casting, a rimmed disk is firstly molded, then cut and shaved to form a gear.

In contrast, plastic’s cure shrinkage is less than metal, and high in dimension accuracy when injection-molding. In addition, plastic also has a high fluidity and can be poured into fine shape dies. Therefore, you can make the gears of the shape exactly same as the gear-shaped die.

However, plastic shrinks a little as being cured, though not to the extent of metal, and securing high dimension accuracy is difficult when making big gears. In such cases, plastic gears may be lightly shaved after injection molding to shape the tooth flank depending on size and material of the gears. You have to be careful when cutting and grinding plastic, as its property doesn’t suit for such works.

Although it costs to make dies, injection molding is suitable for mass production of small gears because you can use the gears almost straight from the dies.

Image : Injection molded gears

Related Links:

塑料齿轮 - 中文版

CFRP Gears