What are hypoid gears?

Hypoid gears were developed by the American Gleason Company. They are cone shaped gears similar to spiral bevel gears except they transmit motion between non-intersecting shafts. The small gear shaft (hypoid pinion side) is offset from the larger gear shaft (hypoid gear side). Given the proper offset amount, the pinion shaft and large gear shaft can pass each other without interference, enabling the shafts to be supported securely on both ends.

Generally, compared with bevel gears, hypoid gears can obtain higher speed reduction. Their large contact ratio allows heavier load transmission compared to similar size bevel gears. Also because of the smooth meshing, it is possible to further suppress noise and vibration. However, the meshing is very complicated and the production itself is more difficult. As for applications, they are mainly used in automotive drive systems such as in differential gears.

As mentioned before, it is possible to obtain very high speed reduction with one pair of hypoid gears. Compared to worm gear drives of similar high speed reduction, hypoid gears generally have the following advantages.

- Both pinion and gear can be heat treated resulting in high rigidity which leads to a smaller unit.

- Less sliding and high efficiency result in smaller capacity motors.

- Compared to worm, the offset between pinion and gear is small with resultant space savings.

Overview of hypoid gears supplied by KHK

Module : 1 – 1.5

Speed ratio : 15 – 60

Material : SCM415

Hardening : Carburizing

Tooth finish : Cut (non-ground)

Grade : JIS 3

Description : Hypoid gears that have been tempered and hardened that are capable of rapid deceleration

Please click High-Ratio Hypoid Gears for more details

Appendix – Hypoid gear

This article is reproduced with the permission.

Masao Kubota, Haguruma Nyumon, Tokyo : Ohmsha, Ltd., 1963.

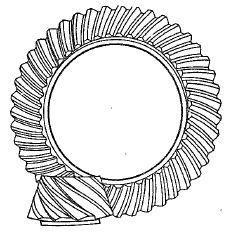

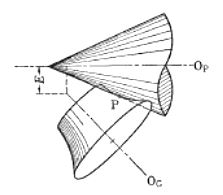

The hypoid gear shown in pic 9.1 is a type of gear whose two axes are neither parallel nor crossed, in other words, skew, having a shape similar to spiral bevel gear. Its pitch surface is composed of a conical surface and a line-contacting surface of revolution (an inscribed cone can be used as a substitute, but it has point-contacts) as shown in pic 9.2. It was developed by Gleason for driving rear axles of automobiles in 1925 in the U.S. It is still mainly used for cars.

Pic 9.1 Hypoid gear

Pic 9.2 Pitch surface of hypoid gear

A Hypoid gear is used when the included angle is square and distance between axes are relatively small. The hypoid gear is viewed as an intermediate between a bevel gear and a worm gear machine. However, a hypoid gear has some advantages over spiral bevel gears as shown below :

Firstly, it increases the flexibility of a machine design because the axis can be extended to both directions and the height of axis can be set freely in some degree.

Secondly, the pinion’s diameter can be broadened because the spiral angle of the pinion is larger than the spiral angle of the gear. As a result, the strength of the tooth is increased and its lifetime will increase several times. In addition, the stiffness of the shafting will also increase by making axis the thick.

Thirdly, the number of teeth can be reduced because of the high contact ratio. As a result, you can choose a speed ratio higher than a bevel gear.

Fourthly, a satisfactory lubrication condition is ensured because a sliding characteristic can be obtained at all points.

On the contrary, there are some disadvantages: it requires high technology in design and manufacturing, and the material and lubrication require special care when meshing so close to point-contact.

相关链接 - 高传动比准双曲面锥齿轮