What is a rack and pinion ?

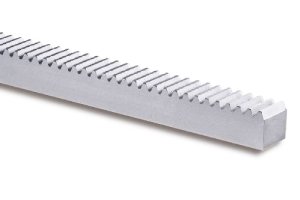

Gear racks are utilized to convert rotating movement into linear motion. A gear rack has straight teeth cut into one surface of a square or round section of rod and operates with a pinion, which is a small cylindrical gear meshing with the gear rack. Generally, gear rack and pinion are collectively called “rack and pinion”. There are many ways to use gears. For example, as shown in the picture, a gear is used with the gear rack to rotate a parallel shaft.

To provide many variations of rack and pinion, KHK has many types of gear racks in stock. If the application requires a long length requiring multiple gear racks in series, we have racks with the tooth forms correctly configured at the ends. These are described as “gear racks with machined ends”. When a gear rack is produced, the tooth cutting process and the heat treatment process can cause it to try & go out of true. We can control this with special presses & remedial processes.

There are applications where the gear rack is stationary, while the pinion traverses and others where the pinion rotates on a fixed axis while the gear rack moves. The former is used widely in conveying systems while the latter can be used in extrusion systems and lifting/lowering applications.

As a mechanical element to transfer rotary into linear motion, gear racks are often compared to ball screws. There are pros and cons for using racks in place of ball screws. The advantages of a gear rack are its mechanical simplicity, large load carrying capacity, and no limit to the length, etc. One disadvantage though is the backlash. The advantages of a ball screw are the high precision and lower backlash while its shortcomings include the limit in length due to deflection.

Rack and pinions are used for lifting mechanisms (vertical movement), horizontal movement, positioning mechanisms, stoppers and to permit the synchronous rotation of several shafts in general industrial machinery. On the other hand, they are also used in steering systems to change the direction of cars. The characteristics of rack and pinion systems in steering are as follows: simple structure, high rigidity, small and lightweight, and excellent responsiveness. With this mechanism, the pinion, mounted to the steering shaft, is meshed with a steering rack to transmit rotary motion laterlly (converting it to linear motion) so that you can control the wheel. In addition, rack and pinions are used for various other purposes, such as toys and lateral slide gates.

Industries that use Rack and Pinion

Robotics

Humanoid Robots

Semiconductor Equipment

Medical Device

Machine Tools

Industrial Automation

Food Processing Equipment

With this technical data you can view comprehensive information regarding KHK gear racks such as their features and advice and warnings when selecting and using them.

SRHEF

Helical Racks

Module : 1.5 – 6

Length : 1000mm

Material : S45C

Hardening : None

Tooth finish : Cut (non-ground)

Grade : KHK R001 4

As they are helical racks, they have higher strength and quietness as compared with SRF. They can be used like CP racks.

Recommended mating pinion

SHE

SHE

Helical Gears

Module : 1.5 – 6

Number of teeth : 18 - 30

Material : S45C

Hardening : Please see details on PDF

Tooth finish : Cut (non-ground)

Grade : JIS N8

SRHEF pinions that have excellent strength and quietness as compared with SS due to its helix. The teeth can be additionally hardened.

Recommended mating rack

SRHEF

ZST / ZSTD

Hardened Ground Helical Racks

Module : 2 - 6

Length : 1000,2000mm

Material : DIN C45 (equivalent to JIS S45C)

Hardening : Gear teeth induction hardened

Tooth finish : Ground

Grade : DIN3962,3963,3967 Q6 (Please see details on PDF)

Helical racks that have been hardened and ground that have excellent accuracy, wear resistance and quietness. They can be used like CP racks. Secondary operations are possible except for tooth.

Recommended mating pinion

ZSTP

ZSTP

Ground Helical Gears

Module : 2 - 6

Number of teeth : 18 - 30

Material : SCM440

Hardening : Thermal refined, gear teeth induction hardened

Tooth finish : Ground

Grade : JIS N6 (Please see details on PDF)

ZST pinions with high accuracy that have excellent strength, wear resistance and quietness due to its helix. Secondary operations are possible except for tooth.

Recommended mating rack

ZST / ZSTD

ZST-GL

Assembly Gauges

Module : 1.5 - 6

Effective Number of Teeth: 3 - 9

Material : S45C

Grade : KHK R001 2

A gauge for assembling ZST/ZSTD helical racks.

Recommended mating rack

ZST/ZSTD helical racks

MRGF / MRGFD

Hardened Ground Racks

Module : 1.5 - 3

Length : 500mm

Material : SCM415

Hardening : Tooth area carburized

Tooth finish : Ground

Grade : KHK R001 1 (Please see details on PDF)

Racks that have been carburized and ground that have excellent accuracy, strength and wear resistance. Secondary operations are possible except for tooth.

Recommended mating pinion

MSGA, MSGB

KRGF-H / KRGFD-H

Hardened Ground Racks

Module : 1.5 - 3

Length : 500,1000mm

Material : SCM440

Hardening : Thermal refined, gear teeth induction hardened

Tooth finish : Ground

Grade : KHK R001 1 (Please see details on PDF)

Racks that have been tempered, hardened and ground that have excellent accuracy, strength and wear resistance. Secondary operations are possible except for tooth.

Recommended mating pinion

KSG

KRG / KRGF / KRGFD

Thermal refined Ground Racks

Module : 1 - 3

Length : 100,500,1000mm

Material : SCM440

Hardening : Thermal refined

Tooth finish : Ground

Grade : KHK R001 1 (Please see details on PDF)

Racks that have been tempered and ground that have excellent accuracy and strength.

Recommended mating pinion

SSG

SRG / SRGF / SRGFD / SRGFK

Hardened Ground Racks

Module : 0.5 – 6

Length : 100,300,500,1000mm

Material : S45C

Hardening : Gear teeth induction hardened (Please see details on PDF)NOTE 2

Tooth finish : Ground teeth

Grade : KHK R001 3 (Please see details on PDF)

Racks that have been hardened and ground with a good balance of accuracy, wear resistance and cost. Secondary operations are possible except for tooth.

Recommended mating pinion

SSG, SSGS

KRF-H / KRFD-H

Hardened Racks

Module : 1.5 – 5

Length : 1000mm

Material : SCM440

Hardening : Thermal refined, gear teeth induction hardened

Tooth finish : Cut (non-ground)

Grade : KHK R001 5

Racks that have been tempered and hardened that have excellent strength and wear resistance. Secondary operations are possible except for tooth.

Recommended mating pinion

KS-H

SRF-H / SRFD-H

Hardened Racks

Module : 1.5 – 6

Length : 1000mm

Material : S45C

Hardening : Gear teeth induction hardened

Tooth finish : Cut (non-ground)

Grade : KHK R001 5

Racks that have been hardened with excellent wear resistance. Secondary operations are possible except for tooth.

Recommended mating pinion

SS-H

SRF-HL / SRFD-HL

Laser Hardened Racks

Module : 1.5 – 6

Length : 1000,1500,2000mm

Material : S45C

Hardening : Gear teeth laser hardened

Tooth finish : Cut (non-ground)

Grade : KHK R001 4 equivalent

Racks that have been laser hardened with a good balance of wear resistance and cost. Secondary operations are possible except for tooth.

Recommended mating pinion

SS-H

SRAF-HL / SRAFD-HL / SRAFK-HL

Laser Hardened Racks

Module : 1.5 – 4

Length : 1000mm

Material : S45C

Hardening : Gear teeth laser hardened

Tooth finish : Cut (non-ground)

Grade : KHK R001 4 equivalent

Racks that have been laser hardened with a good balance of wear resistance and cost. These racks have smaller tooth height and save space in comparison to SRF-HL Racks.

Recommended mating pinion

SS-H

KRF / KRFD

Thermal Refined Racks

Module : 1.5 – 5

Length : 500,1000mm

Material : SCM440

Hardening : Thermal refined

Tooth finish : Cut (non-ground)

Grade : KHK R001 4 (Please see details on PDF)

Racks that have been tempered with excellent strength.

Recommended mating pinion

KS

SRAF / SRAFD / SRAFK

Steel Racks with Machined Ends

Module : 1.5 – 4

Length : 1000, 2000mm

Material : S45C

Hardening : None

Tooth finish : Cut (non-ground)

Grade : KHK R001 4 (Please see details on PDF)

These racks have smaller tooth height in comparison to SRF Racks.

Recommended mating pinion

SS

SR

Steel Racks

Length : 100-500mm

Material : S45C

Hardening : None

Tooth finish : Cut (non-ground)

Grade : KHK R001 4

Many lineups are available at a low price and excellent usability.

Recommended mating pinion

SS

SRF

Steel Racks with Machined Ends

Module : 0.5 – 10

Length : 300-2000mm

Material : S45C

Hardening : None

Tooth finish : Cut (non-ground)

Grade : KHK R001 4

Many lineups are available at a low price and excellent usability.

Recommended mating pinion

SS

SRFD / SRFK

Steel Racks with Bolts Holes

Module : 0.5 – 6

Length : 300-2000mm

Material : S45C

Hardening : None

Tooth finish : Cut (non-ground)

Grade : KHK R001 4 (Please see details on PDF)

Many lineups are available at a low price and excellent usability.

Recommended mating pinion

SS

SUR / SURF / SURFD

Stainless Steel Racks

Module : 1 – 4

Length : 500,1000mm

Material : SUS304

Hardening : Solution treated

Tooth finish : Cut (non-ground)

Grade : KHK R001 5

Stainless steel racks with rust resistance.

Recommended mating pinion

SUS, SUSA

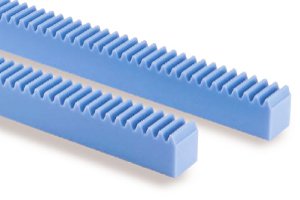

DRF / DRFD / DRFK

Plastic Racks

Module : 1 – 3

Length : 500,1000mm

Material : Polyacetal

Hardening : None

Tooth finish : Cut (non-ground)

Grade : KHK R001 5 (Please see details on PDF)

Racks made of polyacetal with shorter overall length than nylon, making them suitable for joining together.

Recommended mating pinion

SUS, SUSA

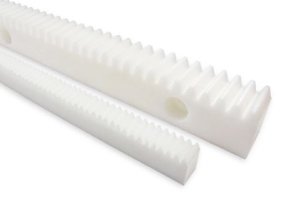

PR /PRF

Plastic Racks

Module : 1 – 3

Length : 500,1000mm

Material : MC901

Hardening : None

Tooth finish : Cut (non-ground)

Grade : KHK R001 5 equivalent

Nylon racks can be used with no lubrication.

Recommended mating pinion

SUS, SUSA

BSR

Brass Racks

Module : 0.5 – 1

Length : 300mm

Material : C3604

Hardening : None

Tooth finish : Cut (non-ground)

Grade : KHK R001 4

Brass racks with excellent machinability.

Recommended mating pinion

BSS

SRO / SROS

Steel Round Racks

Module : 1 – 5

Length : 500,1000mm

Material : S45C

Hardening : None

Tooth finish : Cut (non-ground)

Grade : KHK R001 4

Round racks that are suitable when the rack side moves.

Recommended mating pinion

SS

SURO

Stainless Steel Round Racks

Module : 1 – 3

Length : 500,1000mm

Material : SUS303

Hardening : None

Tooth finish : Cut (non-ground)

Grade : KHK R001 5

Round racks made of stainless steel. Suitable when the rack side moves.

Recommended mating pinion

SUS, SUSA

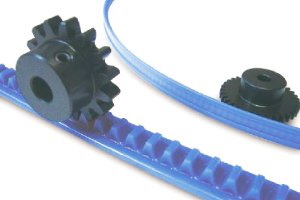

DR

Molded Flexible Racks

Module : 0.8 – 2

Length : 2000mm

Material : Duracon (R) (M25-44) NOTE 4

Hardening : None

Tooth finish : Injection molded

Grade : KHK R001 8

Thin plastic racks that can be bent.

Recommended mating pinion

SSDR

SSDR

Pinions for DR

Module : 0.8 – 2

Number of tooth : 15-35

Material : S45C

Hardening : None

Tooth finish : Cut (non-ground)

Grade : JIS N8 (Please see details on PDF)

Recommended mating rack

DR

KRHG / KRHGF / KRHGFD

Ground Helical Racks

Module : 1 – 3

Length : 100,500,1000mm

Material : SCM440

Hardening : Thermal refined

Tooth finish : Ground teeth

Grade : KHK R001 1 (Please see details on PDF)

Helical racks that have been tempered and ground with excellent accuracy that have higher strength and quietness as compared with KRGF.

Recommended mating pinion

KHG

SRHEF-HL

Laser Hardened Helical Racks

Module : 3 – 6

Length : 1000mm

Material : S45C

Hardening : Gear teeth laser hardened

Tooth finish : Cut (non-ground)

Grade : KHK R001 4

Helical racks that have been laser hardened that have excellent strength and wear resistance in comparison to SRHEF Racks. They can be used like CP racks.

Recommended mating pinion

SHE-H

SRH / SRHF / SRHFD

Steel Helical Racks

Module : 2 – 3

Length : 100,500,1000mm

Material : S45C

Hardening : None

Tooth finish : Cut (non-ground)

Grade : KHK R001 5

As they are helical racks, they have higher strength and quietness as compared with SRF.

Recommended mating pinion

SH

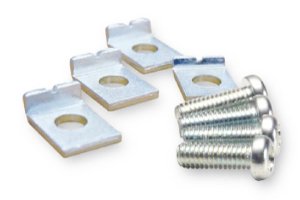

[NOTE 1] The catalog numbers of the above racks with (F) suffix have both ends machined so that they can be butted against each other. The items with (D) have mounting screw holes for immediate assembly.

[NOTE 2] Products with module under 1 are thermal refined without their gear teeth being induction hardened.

[NOTE 3] Precision grade standard of racks are set by KHK. Please see "Precision of Racks" in Selection Hints section for details.

[NOTE 4] "Duracon (R)" is a registered trademark of Polyplastics Co., Ltd. in Japan as well as other countries.

Gear Rack and Pinion – creation of linear motion

A rack and pinion are used when converting rotational movement to linear motion (or vice versa). A bar shaped gear with an infinite (flat surface) radius of a cylindrical gear is called a rack, and a meshed spur gear is called a pinion. A rack can be used by extending it combining as many racks with machining operation on the end faces when necessary.

A helical rack is a bar shaped gear with slanted linear tooth trace that is used when silence and high speed rotation are required, and it can be meshed with a helical gear.

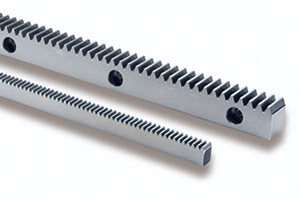

Image : Plastic / Steel racks

Design and Application Examples of Rack and Pinion Mechanisms

Gears transmit power by rotating one gear to move the gear that is meshed with it. On the other hand, in rack and pinion, the combination of rack gear in the form of a gear stretched in a rod form and a small diameter gear (pinion gear) converts rotational motion into a linear motion to transmit power. For example, in a case where the pinion gear is stationary and the rack moves, the pinion is often connected to the output shaft of motors. The driven side of the rack is supported by a separate structure of machine elements. The pinion gear’s repetitive rotational motion produces a repeated forward-backward motion of the rack.

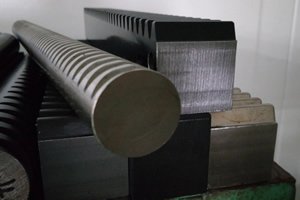

For the power transmission mechanism, the gear is attached to a shaft by means such as with a key, and its shaft is supported with ball or sleeve bearings. In case of a rack and pinion when the driven member is the rack, more creativity in design is needed since the rack is in the form of a rod (circular or rectangular).

When the rack is circular, sleeve bearings on the market can be used and the bearing support structure is relatively simple. On the other hand, to insure the constant meshing of the pinion and the rack, it is necessary to provide for means to stop the rack from rotating. The round racks have the gear teeth cut on the rod so that the cross section is different from the normal gears. They have the shape of a crescent moon with its shoulders shaved off. As a result, their strength is less than that of rectangular racks.

When the rack is rectangular, it becomes necessary to make suitable bearings. In this case, they can also act as the means to stop rack rotation, Also, the cross sections of rectangular racks are, unlike that of round racks, the same as those of gears with the same strength as the gears of the same specifications.

Rack and pinion has the characteristics of its function being drastically altered depending on whether the rack is stationary or movable.

When the rack is movable, its motion is in a straight line, and its use is mainly to take advantage of this behavior. For example, it is used as a jack or clamping system or, by modifying the tip of a rack, utilized as the pusher of a work piece.

When the rack is stationary, the pinion gear rolls on the rack and its application method varies widely. Positioning of machines, hand press, horizontal transport mechanism and elevating mechanism, etc. can be used as examples.

Also, if two racks are laid facing each other and a pinion is placed between them, the repeated forward-backward motion of the pinion will produce an alternating advance and retreat motion of the racks. For applications of this mechanism, work escapement mechanisms and air driven rotary actuators can be listed.

Racks can be placed midstream in conveyor transport mechanisms. By incorporating freely rotating pinions on transport pallets which engage the racks, the items on the pallet can be flipped or rotated. This is one special application example.

As shown, pinion and rack possesses a high degree of freedom in its applications depending only on the users’ ideas.

Rack and Pinion Used in Automotive Steering Mechanisms

The steering mechanism is used to change the direction of automobiles and are mainly classified into rack-and-pinion and ball nut types.

Of these two, the rack and pinion type steering mechanism has become the mainstream used in many small cars. Its construction is simple with other characteristics such as lightweight, high strength, low friction, superior responsiveness, etc.

The rack and pinion type steering mechanism consists of a pinion attached to the tip of the steering shaft on which the steering wheel is mounted. The pinion is meshed with a rack so that the movement of the handle rotates the pinion which in turn moves the rack sideways. The wheel is moved left and right through the system of tie rods connected to the ends of the rack.

(Caution : Currently, KHK does not supply rack and pinion for automotive steering mechanisms.)

Materials and heat treating racks and pinions

As for the materials of a racks and pinions, strength, abrasion resistance, and absorbency are considered.

With steel, S45C (1045 in AISI/SAE, C45 in ISO, equivalent to C 45K in DIN), SCM440 (4140 in AISI/SAE, equivalent to 42CrMo4V in ISO and DIN), 16MnCr5 (name in ISO, equivalent to 17Cr3 in DIN), with stainless steel, SUS303 (303/S30300 in AISI/SAE, 13 in ISO, equivalent to X10CrNiS18-9 in DIN), SUS304 (304/S30400 in AISI/SAE, 6 in ISO, equivalent to X5CrNi18-10 in DIN), with plastic material, reinforced nylon called engineering plastic, polyacetal (equivalent to Duracon and POM), polyamide, are used.

Regarding the heat treatment of a rack and pinion, thermal refining, carburizing and quenching, tooth face high frequency hardening, and tooth face laser hardening are used depending on the kinds of materials and purposes.

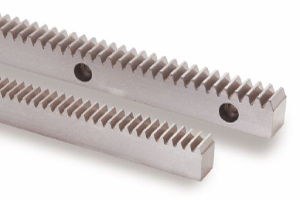

Image : Material of racks

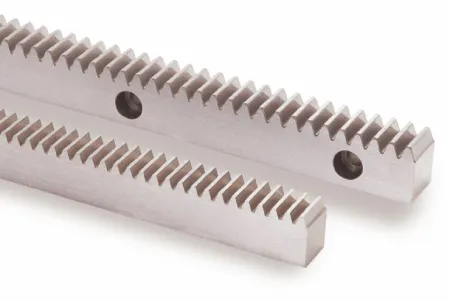

Overall length and cross-sectional shape of a rack

The overall length of standard racks on the market is generally not more than 2000mm, and offered in 500mm units such as 500mm, 1000mm, 1500mm.

Furthermore, the cross-sectional shape is often a square or rectangle, and some are round called round rack type.

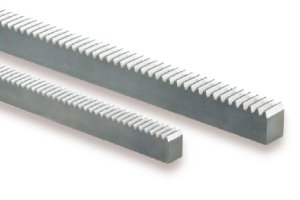

Image : Cross sectional shape of racks

Production of racks and pinions

Although the difficulty in production varies depending on the accuracy classes and specifications, the basic production of the rack and pinion is possible with a rack cutting machine and gear hobbing machine. They are produced by many gear manufacturers and rack specialized manufacturers in the world. They are especially produced on a large scale by famous rack manufacturers in Germany and Taiwan.

Using Racks and Pinions

The rack and pinion are used mainly for carrier devices, steering gear mechanisms for vehicles, machine tools, lifting apparatus, and printing machines.

When attaching a rack to a machine, mounting holes drilled though the bottom or through the side are frequently used, additional methods include counterbored bolt holes and tapped holes.

Image : Rack and pinion used for manual lifting device

The helix angle of helical rack

The helix angle of a helical rack is set at 19 degrees 31’42” by many rack manufacturers. When the helix angle is set like so, the movement when a pinion rotates (for instance one rotation) becomes an exact distance in mm, thus making it user-friendly.

Image : Helical rack

Lubricating Racks and Pinions

As for the lubrication of a rack and pinion, there are several methods used.

One such lubrication system consists of a lubricating device (main body), a tube to deliver the lubricant, a check valve and a special urethane pinion at the end of the tube.

The rack and pinion in this system are lubricated as the lubricant is dispered by the pinion.

Since the pinion injects the lubricant into the mesh as it rotates across the gear rack, the pitch of the rack must be the same as the module of the pinion, and in the case of helical rack and pinions, the rack and pinion must be of the same helix angle and opposite in direction.

Image : Pinion made of urethane

Comparison between racks and pinions and ball screws

As a mechanical element that produces linear motion, a rack and pinion system is often compared with to ball screw.

When compared with a rack and pinion, generally a ball screw has superiorities of accurate positioning, smooth motion with a little friction, and no backlash, on the other hand, ball screws have the disadvantages of higher cost, the difficulty of producing ball screws with long lengths due to deflexion, and unsuitability for heavy loads.

Image : Ball screw in machine tool

Related links :

齿条 - 中文版

CP Racks and Pinions - A detailed description of CP Racks and Pinions

“Raw Material” and “Gear Precision Grade” Equivalent Tables

Gear Nomenclature