Optimized gear manufacturing

The purpose of production activity is to create added value. This also applies to gear manufacturing, and added value creation is conducted through production control for the purpose of achieving QCD (quality, cost, volume and deadline), including everything from the procurement of raw materials such as round bars for cylindrical gears and squared timber for racks to the packaging and shipping of the final products, namely gears.

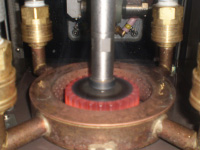

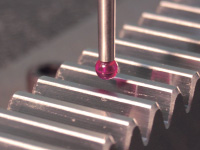

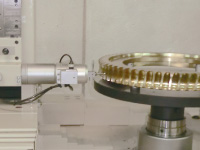

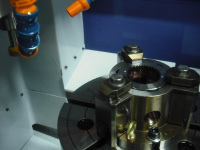

The production process required for gear manufacturing covers a lot of ground, but general examples which can be given include cutting of materials with cutting machines, processing of materials with lathes, cutting of cylindrical gear teeth with hobbing machines, cutting of rack teeth with rack panels, cutting of internal gear teeth with gear shapers, deburring, and blackening, etc. In gear manufacturing processes other than machining mentioned above are also used such as injection molding, sintering, rolling, and casting. Furthermore, polishing, tempering, surface processing, teeth shape measurement, and examination with 3D measurement devices are also components of production activity.

The same as other industries, whether they are made to stock or built to order, optimization of manufacturing by making improvements (Kaizen) is essential in gear manufacturing.

Related links :

Manufacturing of Gears

Production Processes of Spur Gear

Production Processes of Gear Rack

Production Processes of Bevel Gear

Gear Production Facilities

齿轮制造

Kawaguchi Head Factory

This factory mainly engages in the manufacture of custom gears and modifications to gears. With approximately 80 employees, this factory also conducts the design and development of all of KHK’s gears.

Major equipment :

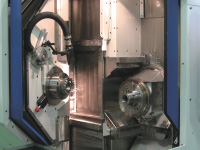

multi-tasking machine (Mazak), vertical machining center (Mazak), vertical machining center (KIRA), CNC gear cutter (Kashifuji), CNC gear grinding machine (Gleason), wire cut electrical discharge machine (FANUC), CNC 3D measurement device (Mitsutoyo)

Noda Factory

This factory conducts the manufacture of almost all types of stock gears as well as the manufacture of all of KHK’s racks and bevel gears including custom gears. There are approximately 120 employees including the 2nd factory, and a reduction of employees via automation of part of the process is also being advanced.

Major equipment :

CNC lathe (Muratec), CNC rack gear cutter (Saikuni), CNC worm grinder (Drake), CNC gear shaper (Mitsubishi), CNC lathe (TSUGAMI), CNC bevel gear tooth cutting machine (Gleason), CNC gear grinding machine (Gleason), vertical machining center (Mazak), CNC spiral bevel gear grinding machine (Gleason), CNC 3D measurement device (ZEISS)

Noda 2nd Factory

High frequency tempering, hardness check after heat treatment, shot blast, worm gear teeth cutting, etc. are conducted here.

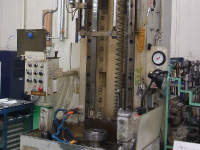

Major equipment :

Laser hardening device (Laserline), high frequency tempering machine (NETUREN)

PRODUCTION EQUIPMENT