1-6 Profile Shifted Gears

When the number of gear teeth to be cut becomes small, the generating tool will sweep out its path, removing some of the profile, and producing an undercut tooth form. To prevent undercut, some correction must be introduced, and it is called profile shifting. Profile shifting can not only prevent undercut, but also can adjust center distance between two gears.

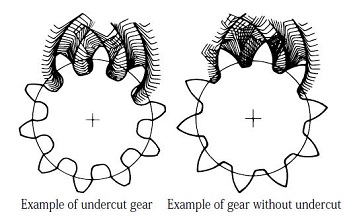

Left : example of undercut gear

Right : example of gear without undercut

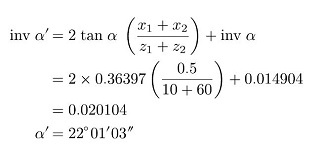

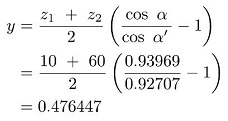

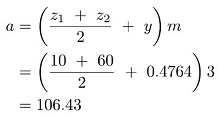

An example of profile shifting is given here.

m=3, z1=10, z2=60, α=20º

The positive correction of 0.5 is to be made on 10-toothed gear (z1=10, x1=+0.5)

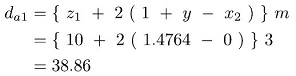

The calculations to be made are :

- Determine working pressure angle α’

- Find center distance modification coefficient, y

- Determine center distance a

- Find tip diameter da

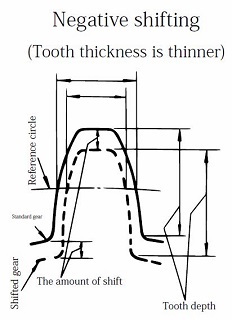

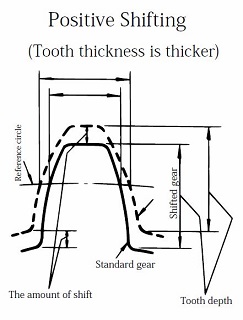

There is both positive and negative shifting. There will be change in tooth thickness; In the case of positive shifting (+), tooth thickness will become thicker, while in the case of negative shifting (-), it will become thinner.

The tooth depth will not change.

Left : Negative shifting (tooth thickness is thinner)

Right : Positive shifting (tooth thickness is thicker)

Important gear terminology :

- Standard gear

- Shifted gear

- Amount of shift

- Reference circle

- Tooth depth

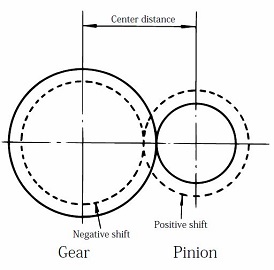

This figure shows a gear that is negative shifted and a pinion that is positive shifted, and the absolute value of profile shift is identical.

Attention is to be paid that there is no change in center distance.

If there is a condition that center distance is invariable and the pinion tooth has undercut, profile shifting will solve the problem as illustrated here.

Important gear terminology :

- Negative shift

- Positive shift

- Center distance

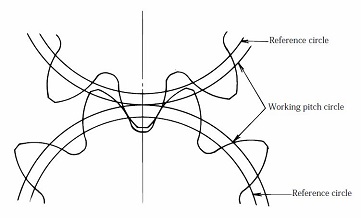

The meshing of standard spur gears means reference circles of two gears contact and roll with each other.

The same of the profile shifted spur gears means working pitch circles of two gears contact and roll with each other.

The pressure angle at the working pitch circle is called working pressure angle.

And this is different from standard pressure angle.

In designing profile shifted gears this working pressure angle will be an important factor.

Reference circle and Working pitch circle

Features :

- Prevents undercutting when the number of teeth is small

- Helps adjusting center distance

- For large gear ratio pairs, the pinion will wear out much faster than the gear.

It is possible to equalize the strengths of a pinion and a gear by profile shifting;

Make correction (shifting) of the pinion positive. Then make correction of the gear negative.

This results in thicker tooth thickness of the pinion and the thinner tooth thickness of the gear, or equalization of the wear life.

Related links :

变位齿轮 - 中文版

Gear Profile Shift