1-8 Materials for Gears and Heat Treatment

The materials herein described are generally used in Japan.

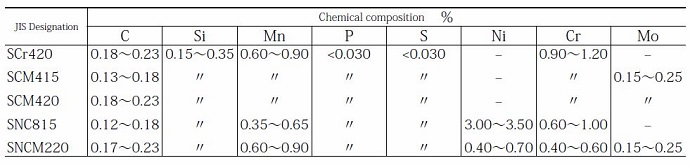

Case-hardening steel

The carbon content of case-hardening steel is low, usually about 0.15 to 0.20% . Case-hardening steel also contains Ni, Cr, Mo, Mn, etc. It is suitable for carburizing and quenching.

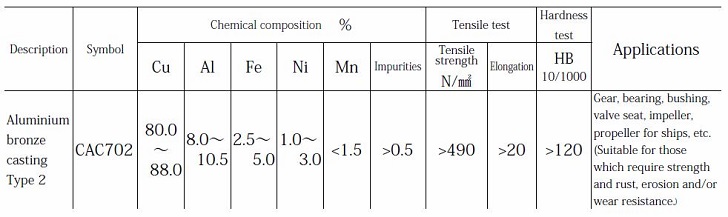

Aluminium bronze casting

Description : Aluminium bronze casting Type 2

Applications : Gear, bearing, bushing, valve seat, impeller, propeller for ships, etc. (Suitable for those which require strength and rust, erosion and/or wear resistance.)

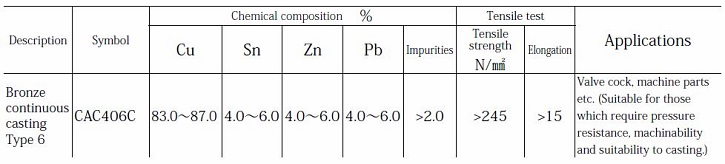

Bronze casting

Description : Bronze continuous casting Type 6

Applications : Valve cock, machine parts etc. (Suitable for those which require pressure resistance, machinability and suitability to casting.)

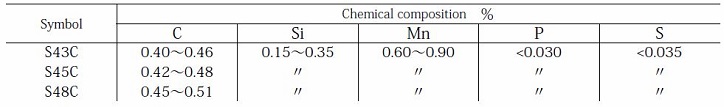

Carbon steels for machine structural use

The most commonly used material. KHK mainly uses S45C. Suitable for high-frequency induction hardening.

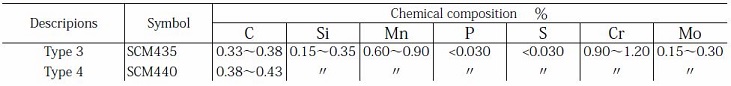

Chromium molybdenum steel

Chromium molybdenum steel is thermal-refined and then hardened by high-frequency induction hardening.

Quenching

Quenching is a process to surface-harden tooth areas to increase their strength.

Cited here are two processes among others – (a) carburizing and quenching, and (b) high frequency induction hardening.

Carburizing and Quenching – The suitable material is SCM415 etc.

Carburizing – Quenching – Cleaning – Tempering – Shot blast – Testing/Inspecting

By heating low carbon steel in carbon gas atmosphere to high temperature and holding, carbon molecules are diffused into the surface making the material similar to S45C.

This, in turn, allows the surface to be hardened by quenching.

– Surface hardness……55 – 60HRC

– Depth of surface hardening……Approx. 1.0mm

(Use thicker depth as the load increases)

Features :

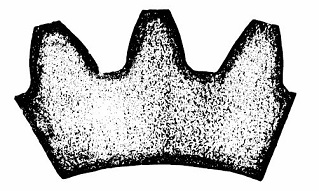

Carburizing and Quenching produces a hard, wear-resistant surface with progressively softer core which retain ductility.

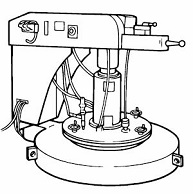

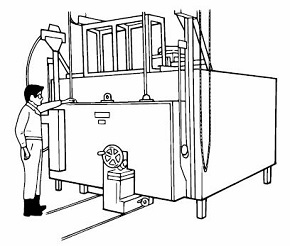

Left : Carburizing & quenching furnace

Right : Hardened layers

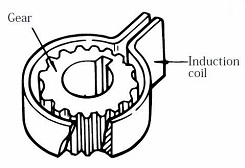

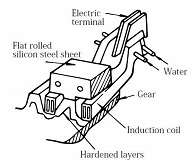

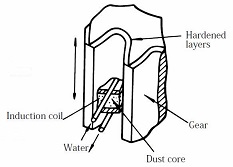

High-Frequency Induction Hardening – The suitable material – S45C, SCM440 etc.

Left : One-shot entire perimeter hardening

Center : One-shot single tooth hardening

Right : Continuous hardening

Thermal refining – Hardening – Tempering

Features :

When heated with the induction coil, the steel is hardened. But the hardened area is limited to the surrounding area of the coil.

In order to reduce the chance of cracking, it is desirable to have material with low sulphur (S) and phosphorus (P) content and carbon content of less than 0.55%.

Various types of induction coils are used depending on the shape of the gear. Some experience is required to do this work as cracking and/or deformation are apt to happen.

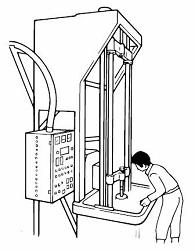

Left : Hardening apparatus

Right : Tempering furnace

Related links :

Hardened Gears

Gear Materials and Heat Treatments

Spur Gears

Gear Materials

Heat treatment of gears