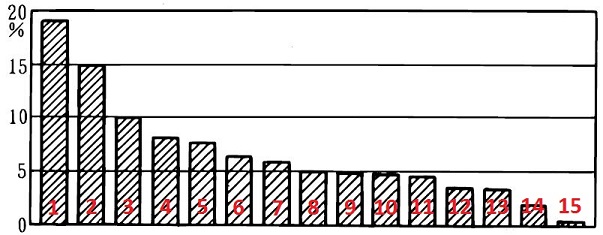

1-9 Gear Noise

This figure indicates the results of a survey conducted by a manufacturer that produces gears for automobile, machine tools and speed reducers.

Cause of noise and vibration :

- Accuracy of gears

- Accuracy of assembly

- Tooth surface finish

- Configuration of gearbox

- Lubrication of gears

- Bearing

- Material of gears

- Design of gears

- Motor and variation of load

- Driving condition

- Shaft and shaft alignment

- Configuration of gears

- Wear of gears

- Surface damage on gears

- Others

Broken down by the factors contributing to gear noise, it becomes :

- Design.......35%

- Fabrication.......30%

- Usage.......20%

- Assembly.......15%

Causes (Items assumed to have effects on noise) :

- Bad tooth contact

- Large pitch error

- Large tooth profile error

- Oscillating torque load on the gear shaft

- Poor tooth surface finish

- Center distance is too small

- Rotation is too fast

- Ball and roller bearings are causing noise

- Gearbox is amplifying noise

- Deformation of gear due to heat treating

In order to manufacture gears that minimize noise during operation :

- Reduce the pitch error

- Reduce the tooth profile error

- Reduce the runout error

- Reduce the lead error

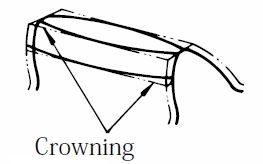

- Modify tooth surface by crowning

- Tip relieving may correct pitch error from tooth deformation

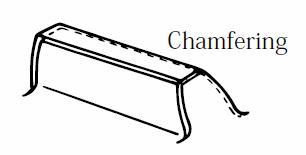

- Remove sharp corners of tooth by chamfering

- Eliminate the roughness on the tooth surface

- Increase the contact ratio – bigger contact ratio lowers the noise

- Try to design gearboxes as close to round shape as possible

- Use a flexible coupling between the prime mover and the gearbox

- Machine the mounting holes of gearbox precisely so that gears can be mounted accurately

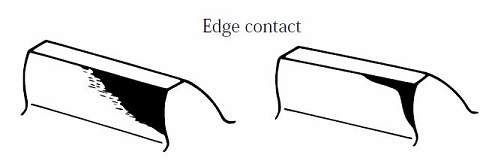

- When assembling gears into gearbox, care must be taken that gears come in contact properly – to avoid edge contact

To improve surface finish, gears are generally shaved or ground. Spiral bevel gears are lapped or ground.

Left : Crowning of tooth

Right : Chamfering of tooth

Example of edge contact

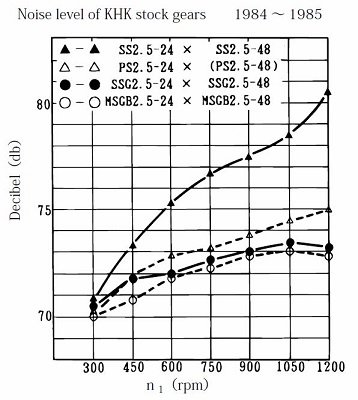

This figure shows an example of data regarding noise level as a result of test on KHK stock gears.

▲ - ▲ : S45C without heat treatment

(SS2.5-24, SS2.5-48)

△ - △ : Plastic

(PS2.5-24, PS2.5-48)

● - ● : S45C Tooth surface high-frequency induction hardened and ground

(SSG2.5-24, SSG2.5-48)

○ - ○ : SCM415 Overall carburizing and quenching, tooth surface ground

(MSGB2.5-24, MSGB2.5-48)

Noise level of KHK stock gears 1984 - 1985

Vertical line – Decibel (db)

Horizontal line – n 1(rpm)

Related links :

齿轮的噪音

Spur Gears – Main page of spur gears

How to reduce Gear Noise – A page of Gear Technical Reference