Induction hardening of gears - Gear Nomenclature

This is a hardening method in which a high-frequency electric current is used to harden the surface of steels that have a carbon content of 0.30% or more.

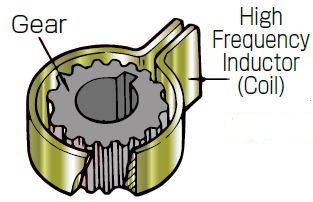

A heating coil (inductor) is used to heat only the gear tooth surface in a short time, followed by rapid cooling which produces hardening.

When induction hardening is applied to gears, the hardening method and the hardened condition of the teeth vary depending on the size of the gear. Even if the tooth surface and tooth tip can be hardened, it may not be possible to harden the tooth root.

Generally, when induction hardening is used, gear accuracy is reduced due to strain after heating, so grinding of the gear teeth is required, if high accuracy is desired.

The typical hardness for induction hardening of S45C steel is 50 - 60 HRC (reference value).