What are hardened gears?

Quenching (surface hardening) of gears is performed to harden and strengthen the tooth surfaces in order to prevent tooth breakage and wear. Quenching significantly improves tooth surface strength in particular. There are several methods of hardening, the most common of which are carburizing, induction hardening, and nitriding.

In carburizing and quenching, carbon is soaked into the surface of low-carbon steel to create a high-carbon state, and the carbon-soaked surface is hardened. Generally, in gas carburizing carbon dioxide gas is widely used. The hardness after quenching is about 55-60HRC, and after quenching, softer portions remain toward the center of the gear, resulting in a hard surface and a tough interior. SCM415 is a common material used for carburizing and quenching. If an anti-carburizing agent is applied to a part of the gear surface to prevent carbon from soaking into it, the hardness of that part can be prevented from increasing.

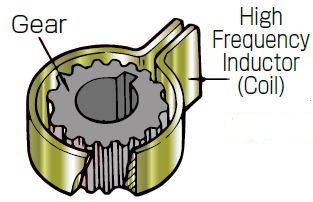

In induction hardening, the surface of gear teeth is hardened by a heating coil (inductor). Common materials used are S45C and SCM440, which contain more than 0.30% carbon, and their hardness after hardening is about 50-60HRC.

When gears are quenched, their accuracy is reduced due to deformation and strain. At that time, a grinding process is required to improve the precision of the gear.

相关链接 - 淬火齿轮