Contact ratio - Gear Nomenclature

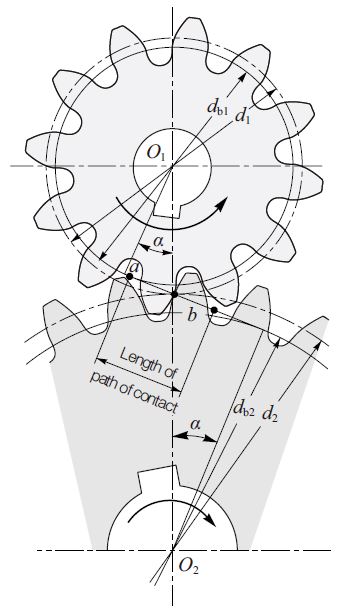

The value obtained by dividing the length of path of contact by the normal pitch (also known as the base pitch) is called the contact ratio.

In gear meshing, the lower the value of the contact ratio, the more load one tooth is subjected to and the greater the deflection and noise of the tooth tends to be.

Gears rotate by repeating "one-tooth meshing" and "two-tooth meshing". The ratio of the frequency of one-tooth meshing to two-tooth meshing is expressed by the contact ratio. The higher the proportion of two-tooth meshing in the total, the higher the contact ratio value.

In the case of one-tooth meshing, the entire load is applied to a single tooth, so the tooth is more likely to break or suffer surface pressure damage.

In the case of two-tooth meshing, the load is shared between the two teeth, so cases with a high two-tooth meshing ratio are superior in terms of strength.

For gears to rotate accurately, the contact ratio must be greater than 1.

For example, if the contact ratio is 1.4, each 0.4 at the beginning and end of the meshing is two-tooth meshing and 0.6 in between is one-tooth meshing.

When gear teeth are shifted, positive shifting results in a larger operating pressure angle and a lower contact ratio. If negative shifting is applied, the operating pressure angle becomes smaller and the contact ratio becomes higher (when there is no undercut).

In helical gears, the teeth are helical, which increases the contact ratio and thus reduces the deflection of the teeth, which in turn reduces noise and vibration.

The value obtained by dividing the length of path of contact by the normal pitch (also known as the base pitch) is called the contact ratio.

相关链接 - 重合度