7. Strength and Durability of Gears / The tooth is the most crucial element of gears. Strength of gears depends on the breakage durability or friction durability.

Gear designers decide specifications in accordance with factors like torque, rotation and expected lifetime. In this section, we briefly introduce the bending strength and the surface durability.

Bending Strength of Spur Gears and Helical Gears JGMA401-01

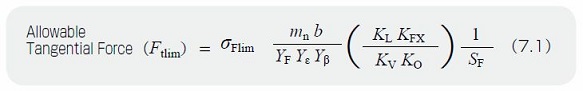

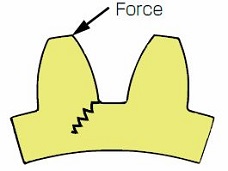

As shown in the Figure.7.1, the tooth fillet breakage occurs at the root when applied force exceeds the limit. The following is the equation for bending stress :

Allowable Tangential Force (7.1)

Fig. 7.1 Lack of bending stress at root

| Symbol | Name | Affected Factors and other Specifications |

|---|---|---|

| σFlim | Allowable bending stress at rootName | Material / Heat treatment |

| mn | Normal Module | Tooth size |

| b | Face Width | Gear size |

| YF | Tooth Profile Factor | Pressure angle/ Profile shift coefficient / Tooth width |

| Yε | Load Sharing Factor | Contact ratio |

| Yβ | Helix Angle Factor | Helix angle of helical gear |

| KL | Life Factor | Expected lifetime |

| KFX | Size Factor of Root Stress | 1.00 at the moment (unknown) |

| KV | Dynamic Load Factor | Circumferential speed / Gear accuracy |

| KO | Overload Factor | Motor / Impact from load |

| SF | Safety Factor | It should be set to more than 1.2 for safety considerations |

How to encourage bending strength

To encourage bending strength, values in the equation for allowable tangential force (7.1) should be set to; The value of denominator should be small & The numerator should be large

- Use durable materials (Increase allowable bending stress at root)

- Enlarge the gear size (For large module / wide tooth width)

- Strengthen tooth profile (Decrease tooth profile factor)

– Large pressure angle

– Positive correction - Increase contact ratio (Decrease load distribution factor)

– Small pressure angle

– Large tooth depth - Improve accuracy

Surface Durability of Spur and Helical Gears JGMA402-01

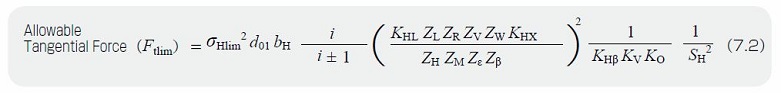

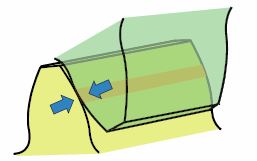

Tooth surface durability is calculated in accordance with the contact stress, to figure out the strength against the tooth surface damage (Pitting).

The allowable tangential force Ftlim for surface durability is;

Allowable Tangential Force (Ftlim)

Fig. 7.2 Contact Stress

| Symbol | Name | Affected Factors and other Specifications |

|---|---|---|

| σHlim | Allowable Hertz Stress | Material / Heat treatment |

| d01 | Pitch Diameter of Pinion | Pinion size (Diameter) |

| bH | Effective Facewidth | Gear size |

| i | Gear Ratio (z2 / z1) | Ratio of the number of teeth |

| ZH | Zone Factor | Helix angle / Profile shift coefficient |

| ZM | Material Factor | Material combination |

| Zε | Contact Ratio Factor | Transverse / Overlap contact ratio |

| Zβ | Helix Angle Factor | 1.00 (Assumed) |

| ZHL | Life Factor | Expected lifetime |

| ZL | Lubricant Factor | Lubricants and Viscosity |

| ZR | Surface Roughness Factor | Surface roughness |

| ZV | Lubrication Speed Factor | Circumferential speed / Surface hardness |

| ZW | Hardness Ratio Factor | Hardness of wheels |

| KHX | Size Factor | 1.00 assumed |

| KHβ | Longitudinal Load Distribution Factor | Gear Support / Stiffness etc. |

| KV | Dynamic Load Factor | Circumferential speed / Gear accuracy |

| K0 | Overload Factor | Motor / Impact from load |

| SH | Safety Factor | Set to more than 1.15 for safety considerations |

How to increase surface durability

- Use hard material treated by quenching ( Increase allowable hertz stress )

- Enlarge gear size (Large pitch diameter / Wide effective tooth width )

- Increase contact ratio (Decrease contact ratio factor )

- Improve accuracy

The strength calculator on KHK web site

The calculation of gear strength tends to be rather complicated. On our web site, we offer a strength calculator for KHK stock gears, which enables you to calculate gear strength automatically, by inputting values in accordance with your usage condition. For gear strength calculation, there are several formulas. The gear strength formula used in our calculator is based on JGMA (Japanese Gear Manufacturers Association) specifications.

Related links :

齿轮的强度

Know about gear transmission torque

Gear Strength and Gear Durability

Bending Strength of Spur and Helical Gears

Surface Durability of Spur and Helical Gears

Bending Strength of Bevel Gears

Surface Durability of Bevel Gear

Surface Durability of Worm Gear