What is a worm gear ?

A worm gear is a type of staggered shaft gear that transmits motion between two shafts that are neither intersecting nor parallel. Even though it is compact it can provide a large speed reduction.

A worm gear is a thread cut into a round bar, and a worm wheel is a gear that meshes with the worm at a shaft angle of 90 degrees. The set of a worm and worm wheel is called a worm gear.

Its history is so old that its existence is described by Archimedes in around 250 BC.

There are roughly two types of worm gears.

One is a cylindrical worm that meshes with a worm wheel as a pair to form the "cylindrical worm gear".

The other is the "drum-shaped worm gear" which is a pair consisting of a drum-shaped worm and a worm wheel.

The latter type is also called "throated worm gear".

When a worm gear is used, a compact and high speed reduction ratio can be obtained as compared with spur gears.

The reduction ratio is determined by the combination of the number of worm threads and the number of teeth on the worm wheel. For example, in the case of the worm gears of the KHK's standard gears, a reduction ratio of up to the maximum of 1/120 can be obtained.

Worm gears have advantages such as low noise and low vibration, but because power transmission is effected by sliding contact, it also has the disadvantage of retaining heat and its transmission efficiency is not high (in the case of a cylindrical worm gear, the general efficiency is about 30 - 60%).

To reduce wear, worms are generally made of a harder material than worm wheels.

For KHK standard gears, mechanical structural carbon steel (S45C), mechanical structural alloy steel (SCM440), stainless steel, etc. are used for worms, while cast iron (FC200), phosphor bronze and aluminum bronze, and MC nylon (an engineering plastic) are used for the worm wheel.

The lead of the left and right tooth surfaces of the worm is normally equal, however there is also another type called dual-lead worm gear which is made with a different lead for the two surfaces.

When using the latter type worm gear, it is possible to move the worm axially by a shim which allows the adjustment of backlash. In cases, such as when tooth wear produces the need for readjustment of the backlash, it can be accomplished without changing the center distance between worm and worm gear.

When using a worm gear, the worm is the driver and the worm wheel is the driven shaft. When the worm's lead angle is especially small, it becomes impossible to turn the worm by the worm wheel.

This condition is called self-locking, and the result of preventing the reverse motion is expected. However, since it is not a totally dependable function, it is desirable to use it in combination with another method when a total prevention of reversal is required.

Examples of worm gear applications include speed reducers, elevators, machine tools, chain blocks, fishing reels and automotive power steering.

Small module worm gears

For high-tech applications such as robotics and medical equipment, small worm gears such as module 0.25, module 0.3, module 0.5 and module 0.8 are ideal.

With this technical data you can view comprehensive information regarding KHK gears such as their features and advice and warnings when selecting and using them.

SW

Steel Worms

Module : 0.5 – 6

Number of start : 1 – 2

Material : S45C

Hardening : None

Tooth finish : Cut (thread rolled)

Grade NOTE 2: KHK W001 4 (Please see details on PDF)

Many lineups are available at a low price and excellent usability.

Mating worm gear : BG, CG, PG, DG

Click Here to Select Worm GearsSWG

Ground Worms

Module : 1 – 6

Number of start : 1 – 3

Material : S45C

Hardening : Gear teeth induction hardened

Tooth finish : Ground teeth

Grade NOTE 2: KHK W001 2 (Please see details on PDF)

Worms that have been hardened and ground with a good balance of accuracy, wear resistance and cost.

Secondary operations are possible except for the teeth.

Mating worm gear : AG

Click Here to Select Worm GearsSUW

Stainless Steel Worms

Module : 0.5 – 3

Number of start : 1 – 2

Material : SUS303

Hardening : None

Tooth finish : Cut (non-ground)

Grade NOTE 2: KHK W001 4 (Please see details on PDF)

Stainless steel worms with rust resistance.

Mating worm gear : BG, CG, PG, DG

Click Here to Select Worm GearsKWG

Ground Worm Shafts

Module : 0.5 – 6

Number of start : 1 – 2

Material : SCM440

Hardening : Thermal refined, gear teeth induction hardened

Tooth finish : Ground teeth

Grade NOTE 2: KHK W001 2

Worms with shafts that have been tempered, hardened and ground that has excellent accuracy, strength and abrasion resistance.

Secondary operations can be given except for the teeth.

Mating worm gear : AG Module 0.5-1.5, AGF

Click Here to Select Worm GearsKWGDL / KWGDLS

Duplex Worms

Module : 1.5 – 4

Number of start : 1

Material : SCM440

Hardening : Thermal refined, gear teeth induction hardened

Tooth finish : Ground teeth

Grade NOTE 2: KHK W001 1

Duplex worms (with shafts) that have been tempered, hardened and ground that has excellent accuracy, strength and abrasion resistance.

Secondary operations can be given except for the teeth.

Moving it in axial direction will adjust the backlash.

Mating worm gear : AGDL

Click Here to Select Worm Gears Click Here to Duplex Worm GuideBG

Bronze Worm Wheels

Module : 0.5 – 6

Speed ratio : 10 – 60

Material : CAC502 (PBC2)

Hardening : None

Tooth finish : Cut (non-ground)

Grade NOTE 2: KHK W002 4 (Please see details on PDF)

Worm wheels made of phosphorus bronze with excellent wear resistance.

Used in combination with SW and SUW.

Mating worm : SW, SUW

Click Here to Select Worm GearsCG

Gray Iron Worm Wheels

Module : 1 – 6

Speed ratio : 10 – 120

Material : FC200 (Please see details on PDF)

Hardening : None

Tooth finish : Cut (non-ground)

Grade NOTE 2: KHK W002 4 (Please see details on PDF)

Cast iron worm wheels that are inexpensive and suitable for light loads.

Used in combination with SW and SUW.

Mating worm : SW, SUW

Click Here to Select Worm GearsPG

Plastic Worm Wheels

Module : 0.5 – 3

Speed ratio : 10 – 50

Material : MC901

Hardening : None

Tooth finish : Cut (non-ground)

Grade NOTE 2: KHK W002 5 equivalent

Worm wheels made of MC nylon. Can be used with no lubrication.

Used in combination with SW and SUW.

Mating worm : SW, SUW

Click Here to Select Worm GearsAG NOTE 1

Worm Wheels

Module : 1 – 6

Speed ratio : 10 – 60

Material : CAC702 (AlBC2) (Please see details on PDF)

Hardening : None

Tooth finish : Cut (non-ground)

Grade NOTE 2: KHK W002 2 (Please see details on PDF)

Worm wheels made of aluminum bronze with a good balance between machinability and wear resistance.

Used in combination with SWG.

Mating worm : SWG

Click Here to Select Worm Gears Click Here to E-series for AGAG NOTE 1

Worm Wheels

Module : 0.5 – 1.5

Speed ratio : 10 – 60

Material : CAC702 (AlBC2)

Hardening : None

Tooth finish : Cut (non-ground)

Grade NOTE 2: KHK W002 2 (Please see details on PDF)

Used in combination with KWG.

Mating worm : KWG

Click Here to Select Worm GearsAGF NOTE 1

Worm Wheels

Module : 2 – 6

Speed ratio : 10 – 60

Material : CAC702 (AlBC2) (Please see details on PDF)

Hardening : None

Tooth finish : Cut (non-ground)

Grade NOTE 2: KHK W002 2

Worm wheels made of aluminum bronze with a good balance between machinability and wear resistance.

Used in combination with KWG.

Mating worm : KWG

Click Here to Select Worm Gears Click Here to E-series for AGFAGDL

Duplex Worm Wheels

Module : 1.5 – 4

Speed ratio : 20 – 60

Material : CAC702 (AlBC2) (Please see details on PDF)

Hardening : None

Tooth finish : Cut (non-ground)

Grade NOTE 2: KHK W002 1

Duplex worm wheels made of aluminum bronze with excellent accuracy and a good balance between machinability and wear resistance.

Used in combination with KWGDL or KWGDLS.

Mating worm : KWGDL, KWGDLS

Click Here to Select Worm Gears Click Here to Duplex Worm Guide Click Here to E-series for AGDL

[Note 1] FC200 is the material for the hubs of AGF and AG worm wheels. The AG worm wheels are normally combined with the SWG worms, but are also compatible with the KWG worms with module 1.5 and below .

[Note 2] The precision grade of KHK stock worm gears controls the product quality based on the KHK standards. Please see "Precision of Worm Gears" on Page 396 in the Selection Hints section for details.

Table of Worm and Worm Gear Combinations

Please click on the diagram below. You can confirm the combinations of the KHK’s standard worms and worm gears in an enlarged table.

Worm Gear – compact design

This article is reproduced with the permission.

Masao Kubota, Haguruma Nyumon, Tokyo : Ohmsha, Ltd., 1963.

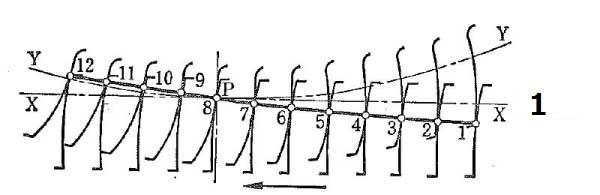

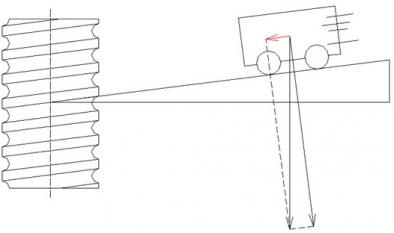

Worm gear is one type of gear device in which the two shafts are at a right angle or near right angle and non-intersecting. There are one or more teeth which are screw shaped, resulting in a gear that looks like a worm. The mating gear is called a worm wheel; together they are called worm and worm wheel or simply worm gear (worm gear device). As shown in Figure 6.1, a high ratio speed reduction in a small space can be obtained compared to spur gears. Therefore when a large speed reduction is desired in one quick stroke, it is common practice to use the worm as the prime mover. However, on rare occasions, the worm wheel is used as the prime mover in a speed increasing application.

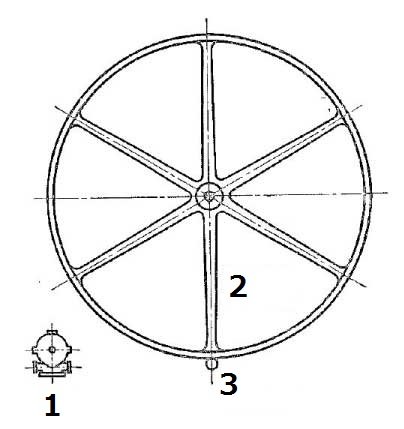

Figure 6.1 Comparison of Sizes between Worm Gear and Spur Gear

1. Reduction ratio 1 : 126

2. 1512 teeth / 40’ diameter

3. 12 teeth / 4’ diameter

Origin of Worm Gears

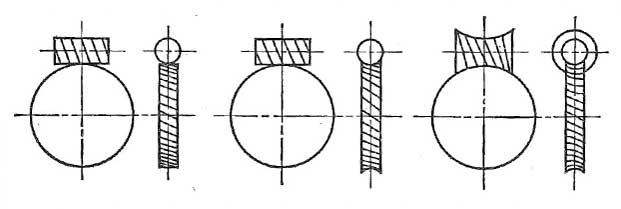

In the case of when two axes are non-intersecting, consider a pair of screw gears in which the pinion gear teeth have been reduced to one or few teeth. Then the pinion becomes the shape of an ordinary screw and a large speed reduction can be obtained as shown in Figure 6.2(a). At this point, the meshing is point contact and can carry only a small load and tends to create friction. However, by using a hob cutter in the shape of the pinion and rotating the cutter equivalent to the motion of worm against the worm wheel, it is possible to obtain a gear set with a line contact. This is the usual worm gear shown in Figure 6.2(b) where the small gear is the worm and the larger gear is the worm wheel.

Figure 6.2 Types of Worm Gears

(Left) Cylindrical Worm and Helical Gear

(Center) Cylindrical Worm and Worm Wheel

(Right) Hourglass Shape Worm and Worm Wheel

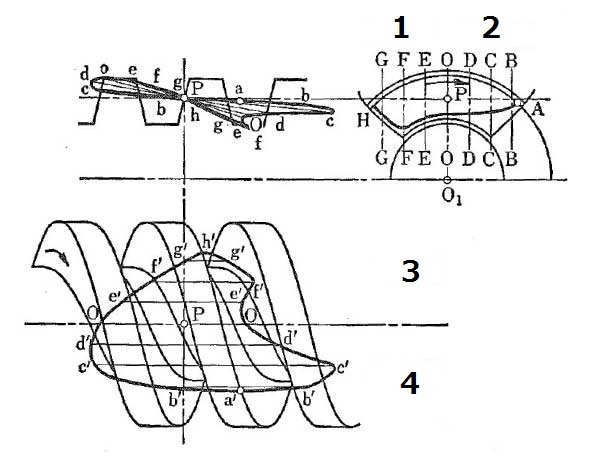

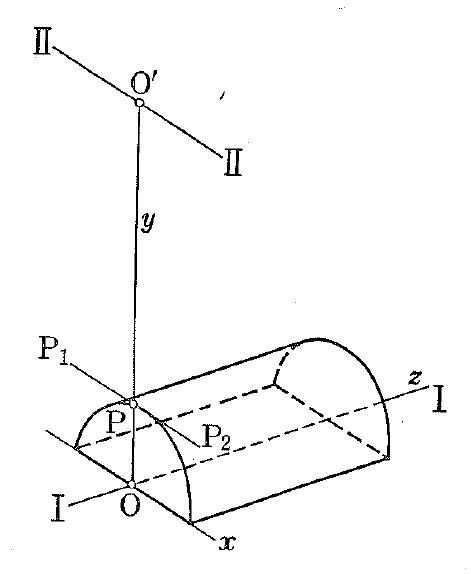

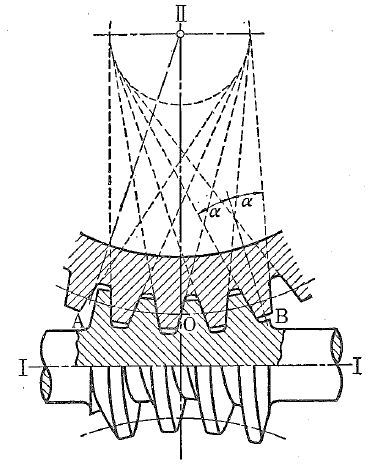

Since the two shafts are normally at a right angle, the rest of discussion will focus on this configuration. The tooth surface of the above worm gear is the worm’s enveloping surface. However, if we consider the cross section perpendicular to the worm wheel shaft, it becomes the rack and pinion mesh in which the tooth surface of the worm is the rack and the tooth surface of the worm wheel is the pinion. The cross section normal to the worm wheel shaft including the worm shaft is called the central cross section. This surface is the boundary between the worm’s advancing side and receding side. As shown in Figure 6.3, the contact situation between them is considerably different.

The common tangent at an arbitrary point on the contact line on both surfaces of the worm wheel always passes through the contact point (pitch point) of the two pitch cylinders and intersects the line parallel to the worm wheel shaft (pitch line, P1P2, in Figure 6.4).

There are many tooth forms for worms, but for the convenience of production, the line weave twist surface or approximation of the line weave twist surface is often used. It is normally the trapezoid based on the central cross section, cross section perpendicular to tooth or normal to the root cross section. However, there are others such as involute worms using involute helicoids and convolute worms using a straight line that intersects the involute worm generating line as its generating line.

1. Advancing Side

2. Receding Side

3. Advancing Side

4. Receding Side

1. Advancing Side

1. Receding Side

Figure 6.3 Comparison of Meshing Conditions of Central Cross Section of Both Sides (Worm’s Advancing Side and Receding Side) (the Left Tooth Surface of the Worm is the Acting Surface)

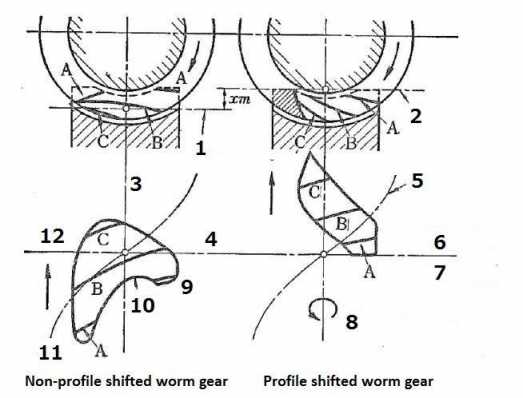

In order to increase the load carrying capacity, sometimes different tooth shape worms are used such as when the central cross section is a circular arc or various secondary curves. Consider each cross section parallel to the central cross section, and the pitch point as the boundary, the receding arc is a smoother mesh than the advancing arc, as in spur gear meshes. Therefore, there are times when the worm is negatively shifted (make worm’s addendum larger and dedendum smaller) so that the majority of the mesh is on the receding arc (Figure 6.5). In particular, if the worm is to be all addendum, it is desirable to have the sum of the number of teeth of both gears to be greater than 40.

Figure 6.4 The Shafts of Worm (I) and Worm Wheel (II) and the Pitch Line P1P2

Figure 6.5 Comparison of Non-profile Shifted vs. Profile Shifted Worm Gear

1. Pitch surface

2. Pitch surface

3. Central cross section

4. Pitch generating line

5. Pitch winding line

6. Receding side arc

7. Advancing side arc

8. Rotation of worm

9. Plan view of contact line on worm

10. Meshing area

11. Start

12. End

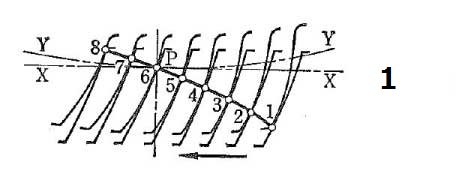

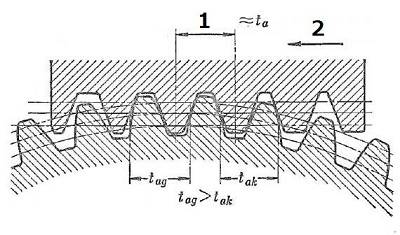

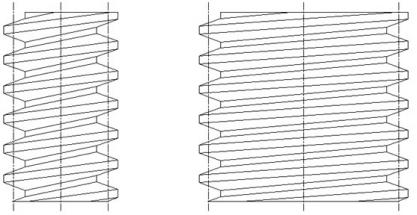

The lead on the right and left tooth surfaces of worms are normally the same. If it is varied as shown in Figure 6.6 so that the worm’s tooth thickness gradually changes in the shaft direction, then it is possible to adjust the backlash by moving the worm in the direction of its shaft. This is called the dual lead worm gear (duplex worm gear) and it is used to accurately eliminate the play in, for example, the hobbing machine’s main worm gear.

Figure 6.6 Dual Lead Worm Gear

(a) Dual Lead Worm Gear

(b) Central Cross Section of Dual Lead Worm Gear

1. Maximum adjustment amount ≈ ta

2. Direction of adjustment

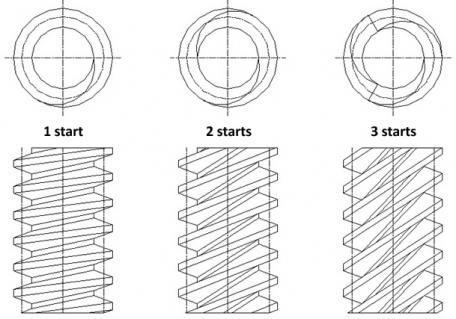

Number of Threads in Worms

The number of threads in a worm is the number of teeth in a worm.

The speed transmission ratio of a worm and worm gear set is obtained by dividing the number of teeth of the worm gear by the number of threads of the worm.

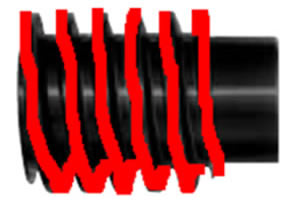

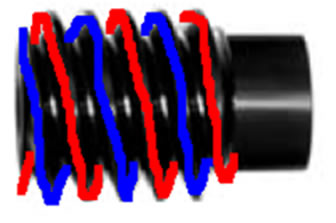

When the number of threads of a worm is one, as the worm shaft rotates once, the worm gear advances one tooth, while when the number of threads of a worm is 2, the worm gear moves just two teeth. This indicates that a set of worm-worm gear can achieve great speed reduction in one step. By the way, when there are more than two threads in a worm, it is called multi-thread worm.

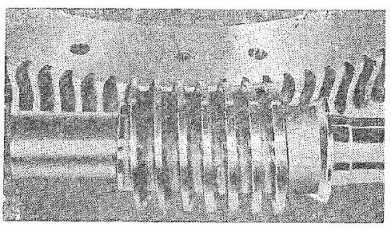

The photo below on the left shows SW2-R1, KHK’s standard worm, while the right photo shows SW2-R2. The number of threads of SW2-R1 is one (red line) and that of SW2-R2 is two (red and blue lines). For the two, the advancing angle of the teeth are also different.

SW2-R1

SW2-R2

When the number of threads of a worm changes, so does the mating worm gear. In the case of KHK standard gears, double threaded SW2-R2, for example, cannot be used with CG2-50R1 which should be matched to a single thread worm. Also, as a set of worm gears, there are right hand and left hand threads so that, for example, right hand thread worm and left hand thread worm gear cannot be used together.

By the way, the single thread combination below yields a speed reduction ratio of 50, while the double thread combination produces a speed reduction ratio of 25.

Duplex Worm Gear to adjust backlash

The objectives, characteristics and how to use duplex worm gears is briefly listed below.

In order to adjust worm gear backlash or to reduce the increased backlash due to wear, it is very difficult to change the center distance between the worm gear and worm without a possible major design modification. The duplex worm gear was designed to address this problem and it is suitable in applications where a small backlash high precision is needed. In this system, the worm gear side has the same tooth thickness around the circumference as other cylindrical gears, but on the worm side, different leads are used for the opposite tooth face leading to continuously changing tooth thickness. After the center distance is fixed, the actual adjustment of backlash is done by moving the worm axially with shims or screws. KHK’s standard duplex worm gears are designed to change the backlash by 0.02mm when the worm is moved axially by 1mm. In all cases, we do not recommend zero backlash since it is necessary to maintain a certain level of backlash in order to prevent the disruption of oil film.

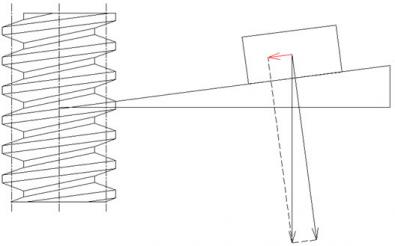

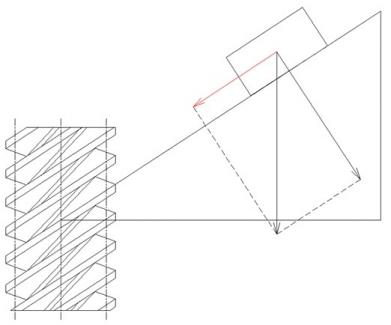

Principle of Self-Locking Feature of Worm Gears

Self-locking means it is not possible to drive the worm using the worm wheel, and this feature is used in such things as reversing prevention systems and roll-up mechanisms.

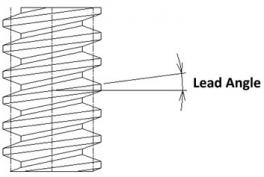

A worm gear’s self-locking tendency increases as the lead angle decreases (It becomes easier to self-lock).

As the lead angle gets larger, it becomes less self-locking.

Number of threads of worm

If worms’ modules and pitch diameters are the same, the lead angle becomes larger as the number of threads increases, that is, it is easier to self-lock when the number of threads is smaller.

Pitch diameter of worm

If worms’ modules and numbers of threads are the same, the lead angle becomes smaller as the pitch diameter gets larger, that is, it is easier to self-lock when the pitch diameter is larger.

When the lead angle is small

Because the force shown in the red arrow is small, the turning force < coefficient of friction, and self-locking occurs.

When the lead angle is large

Because the force shown in the red arrow is large, the turning force > coefficient of friction, there is no self-locking.

Others

Ball screws have small coefficient of friction due to the rolling contact at the screw.

Even though the force shown in the red arrow is small, the turning force > coefficient of friction, and there is no self-locking.

Problem areas of Self-Locking

Because it is relying on the coefficient of friction, self-locking lacks stability.

- Even with the same lead angle, it is difficult to self-lock with materials which have small coefficients of friction (μ)

Example :

Material Combination / Coefficient of Friction

iron and iron / about 0.3

Material Combination / Coefficient of Friction

iron and aluminum bronze / about 0.2

Material Combination / Coefficient of Friction

iron and phosphor bronze / about 0.15 - Coefficient of friction changes with speed

When stationary, the static friction is high, but as the speed increases, it becomes dynamic friction, and the coefficient of friction decreases. When there is vibration, it is possible to reverse rotate. - Coefficient of friction is smaller when the surface roughness is low

It is difficult to self-lock with ground worms.

Hourglass worm gear

This article is reproduced with the permission.

Masao Kubota, Haguruma Nyumon, Tokyo : Ohmsha, Ltd., 1963.

There are special types of worm gears, whose pitch surface is gained by a rotating arc which fits the part closest to the worm of pitch circle around the worm shaft in central section (see Pic 6.2(c)), thus providing a tooth profile of a worm gear in central section, making the dedendum by using the cutter appropriate for the tooth profile, then making the teeth of worm gear with the hob whose tooth profile is same as the dedendum, or by providing the dedendum of worm gear and making the worm using the cutter appropriate for the dedendum. The Hindley worm or cone worm correspond to the former and have straight-line teeth profile in central section as in Pic 6.9, while plane worm gear corresponds to the latter and uses plain surface as the dedendum of worm gear. Some worm gears use involute helical gear. This type of worm gear usually meshes near the central section (as for Hindley worm, all the teeth of the worm are constantly in line contact in central section) and has larger loading capability, but needs to be assembled precisely.

Pic 6.9 Hindley worm

Related links :

Types of Gears - A detailed description of Types of Gears

Gear Rack and Pinion - A detailed description of Gear Rack and Pinion

“Raw Material” and “Gear Precision Grade” Equivalent Tables

蜗杆蜗轮 - 中文页